![]()

Perancea's RoHS Compliant Alternative to Hot Tin Dipped Shielding

Perancea’s new Bright Acid Tin finish for its steel RFI/EMI shielding products provides a solderable lead-free metal plating to comply with the ROHS Directive. As well as meeting green and environmentally friendly legislative requirements, the extremely cost effective new finish is also cosmetically superior to the hot tin dipping process that it replaces.

Perancea’s Bright Acid Tin process is available to three main specifications all of which are ideal for soldering. The good commercial grade provides a nominal plating thickness of 10 microns. To meet BS1872: 1984 service condition No 2 requirements for indoor with some condensation applications, plating can be provided to a minimum thickness of 10 microns and for Def Stan 03-8 Issue 1 specifications, plating is to a minimum average thickness of 25 microns. The process uses less than 0.1% lead, mercury, cadmium, hex chromium or polybrominated diphenyl ethers.

The ROHS Directive sets out to protect human health and the environment by restricting the usage of certain hazardous substances in new equipment. It also sets out to complement the WEEE Directive and involves manufacturers, sellers, distributors and recylers of electrical and electronic equipment containing lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls or polybrominated diphenyl ethers.

The Perancea Bright Acid Tin process provides a uniformly bright finish with excellent solderability and fusing characteristics even after long periods of storage. The finish is also an excellent conductor and provides protection against corrosion. The deposited tin plate is ductile, bright and attractive.

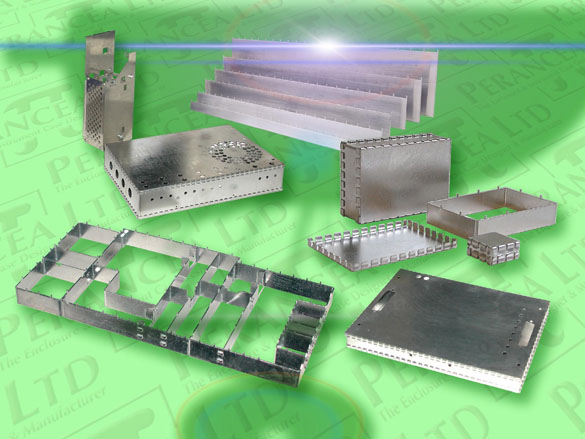

Perancea’s RFI/EMI metal enclosures and screening strips are available in a wide range of designs and sizes for a host of applications from board and component level to sub-assemblies and equipment.

Perancea is a highly experienced mechanical engineering company specialising in the production of RFI/EMI shielding and other enclosures for the electronics and associated industries. The company, with its expertise, is also able to provide custom shielding and enclosure services to meet the needs of the broad range of application requirements from mechanical to electrical and electronics engineering applications.