![]()

Perancea Screening Strips Solve EMI/RFI Problems At Board Level

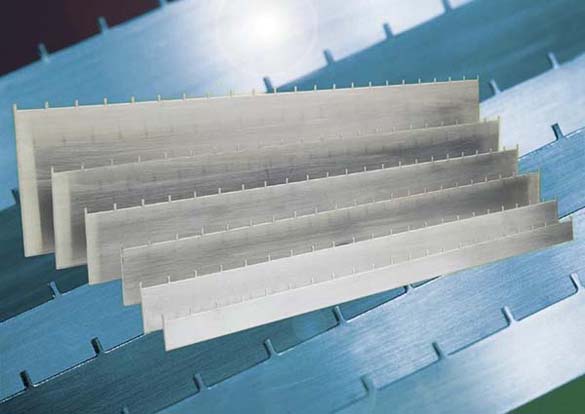

Perancea's range of RFI/EMI metal screening strips provide an ideal solution for segregating sensitive devices and assemblies on circuit boards. The strips can be arranged to 'fence off' selective and even complex area shapes on a PCB, either eliminating or minimising interference between different parts of the circuit, providing a highly versatile and economical board level solution compared to full enclosure screening.

Screening strips are available in a range of standard heights to suit standard enclosures. They come in 232mm lengths and are easily cut to required length, bent and soldered to suit individual applications, enabling from the simple to even labyrinthine solutions for multi-segmented areas to fully optimise discrete screening.

Available standard heights, when mounted on a PCB, are 10, 15, 20, 25, 35 and 50mm. PCB location pins as standard are 1mm wide by 2.5mm long.

As an option, Perancea can supply its new screening strips with the company's unique locking pin mechanism designed to keep the 'enclosure' in place during reflow, wave and hand soldering operations. The new locking pin ensures full contact between the strip and the solder paste in surface mount applications. The pins are easy to activate, using the minimum of effort and guaranteeing high reliability solder joints with optimum EMI/RFI screening performance.

As an extension to the service, Perancea is also able to supply non standard heights and lengths to suit customer requirements without associated tooling charges, making the service ideal for prototyping and low volume production solutions too. 'Fencing' designs can be constructed and supplied either spot welded or with tab and slot locators for easy positioning.

Perancea RFI/EMI screening strips are manufactured as standard in 0.54mm bright steel, electrolytically tin plated to BS2920. Surface resistivity is 20x10-6 ohm/m2 and conductivity is 5x104mho. The screening is manufactured to general tolerances of +/-0.25mm and to within +/-0.1mm on PCB pin pitch. Screening enclosures can also be manufactured in a wide range of gauges, materials and finishes including copper, brass, tinplate, nickel plate and also nickel and bright tin.

For custom screening

enclosure applications, Perancea is able to adapt its production processes to

cater for most requirements notably without tooling charges, making prototyping

and low volume requirements an extremely cost effective and viable proposition.